dm3d-designs

Air Arms S200 / Chiappa FAS-611 Magazine System

Air Arms S200 / Chiappa FAS-611 Magazine System

Couldn't load pickup availability

|

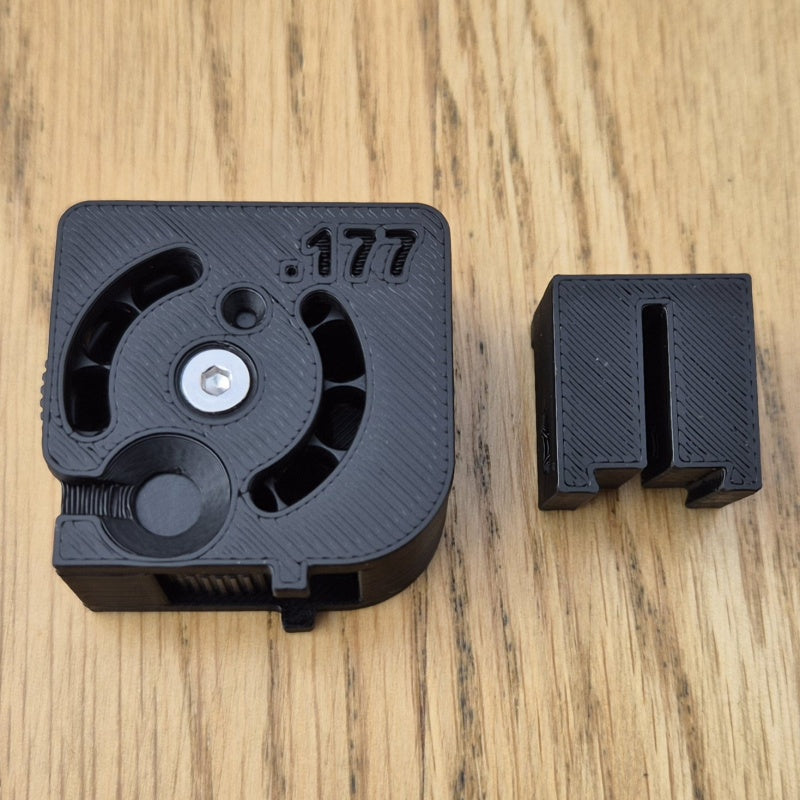

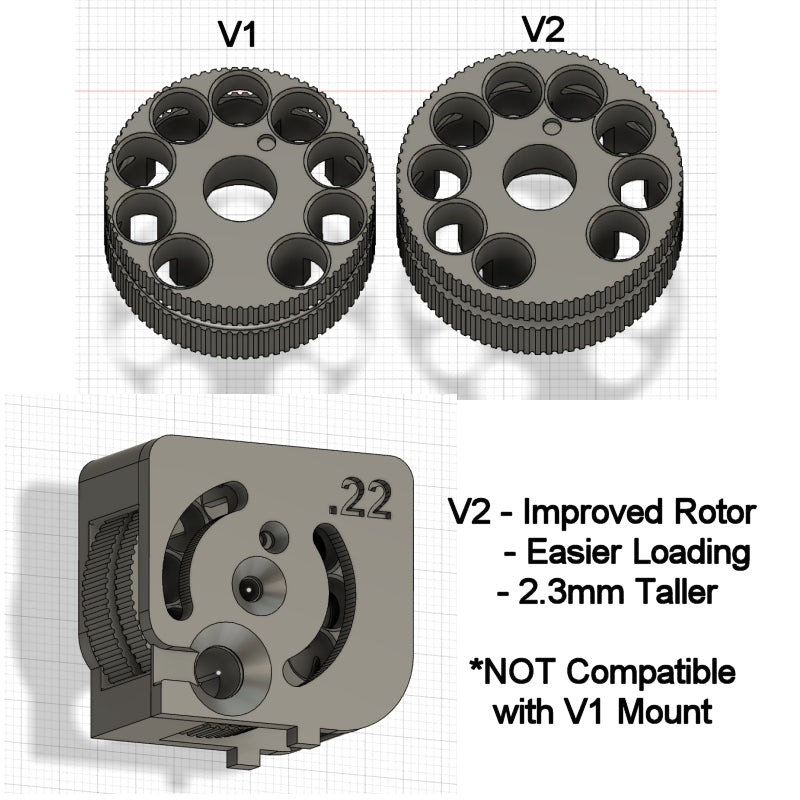

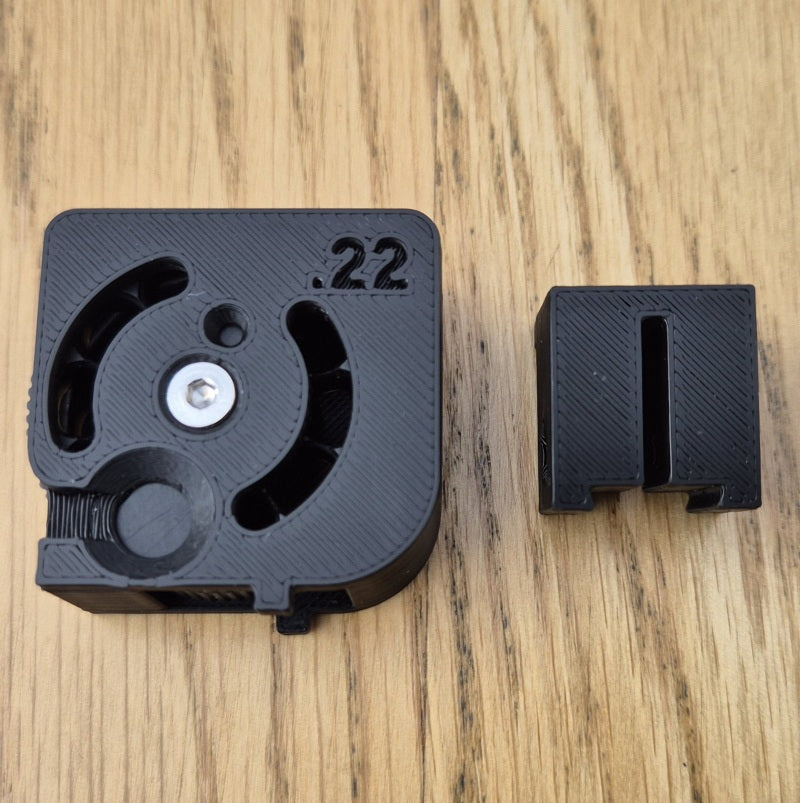

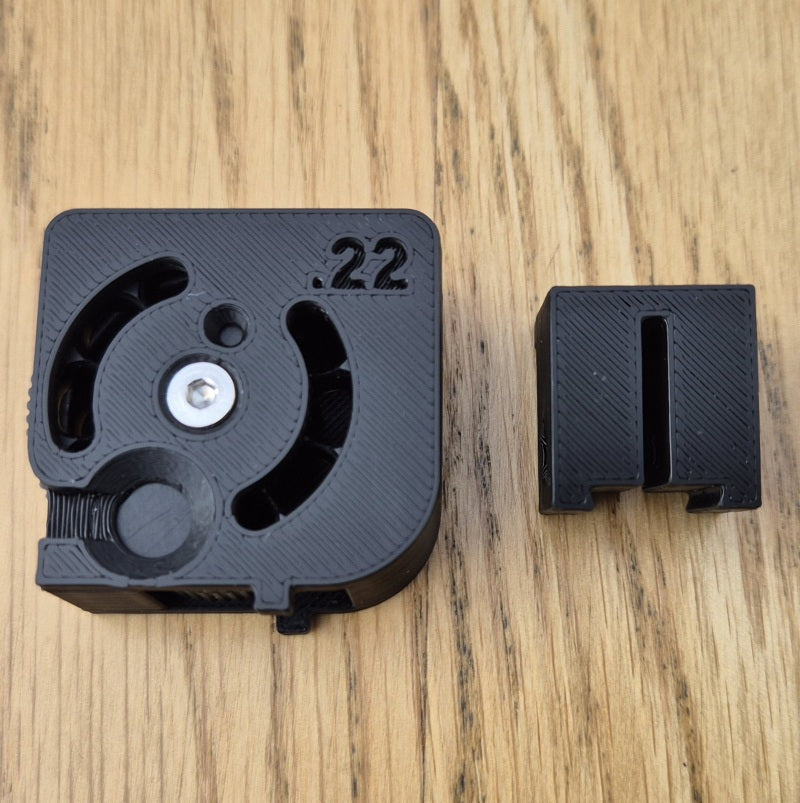

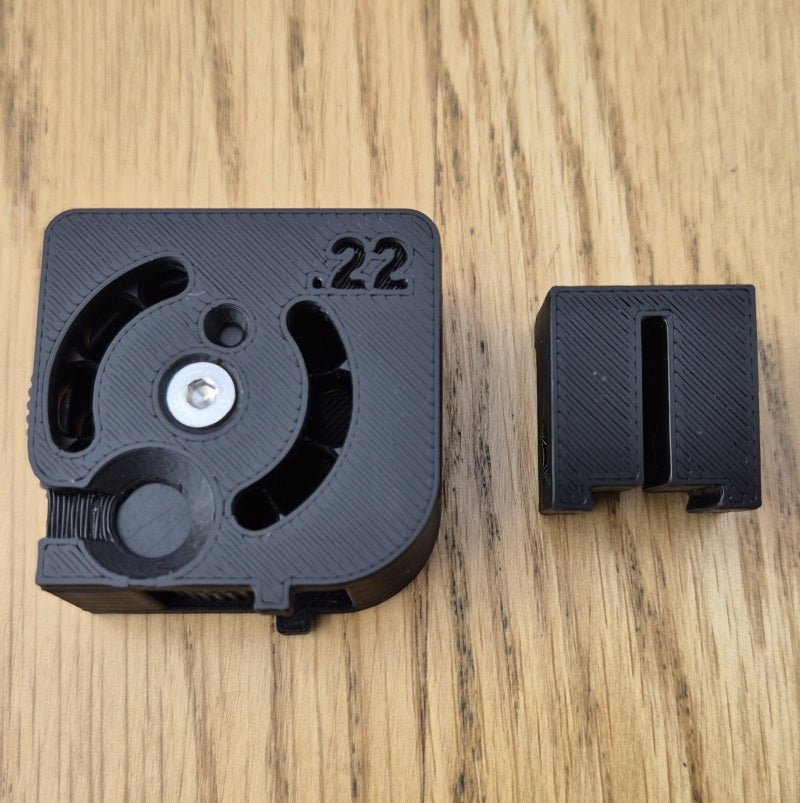

High quality 3D printed Magazine System for the Air Arms S200 and Chiappa FAS-611 airguns. TESTED, APPROVED and STOCKED by THE RAT WORKS!! "DM3D Designs have created this self indexing magazine system that puts the factory multishot conversion to shame. These magazines are high quality 3D printed with extremely durable resin printed internal rotors, an excellent combination that gives the users a quality item for smooth cycling, which improves consistency and accuracy over the standard unit to make the S200 and even more versatile air rifle." *Please note: A small notch will need to be filed or cut away from the stock on the right side when fitting to S200 MK1 And MK2 models. Please see pictures. *Magazines are compatible with both the S200 and FAS-611. When ordering a complete magazine and mount set for the FAS, please select the FAS-611 specific option as the mounting block is slightly different. The magazine and mount is 36mm tall, if you measure from the bottom of the breech slot to ensure it will fit under your chosen scope or optics, high scope mounts may be required. All magazines have a tough and durable resin based internal rotor. These rotors have great detail and are extremely tough and hard wearing. The magazine is a perfect fit, cycling pellets with a super smooth action. Pellets are loaded nose first from the front of the magazine. The magazine is held in place by strong magnets, one in the magazine mount and one in the back of the magazine. The magazine has slots in the face so you can see the number of shots remaining as well as a final shot indicator. The bolt is blocked when empty, so you know to reload. Installing the Magazine System

Loading the magazine

Every magazine is tested prior to shipping. Orders will normally ship the next working day, on rare occasions it could be up to 3 working days depending on stock levels. Due to the materials used in the 3D printing process, do not leave the magazines in direct sunlight or extreme hot temperatures such as conservatories or the dashboard of a car for long periods of time or warping may occur. |

|

|

Share